Quite a few years ago, Dogfish Head founder Sam Calagione worked with Dr. Patrick (Pat) McGovern to re-create an ancient brew based on a chemical analysis of residue found in 9000-year-old pottery from the Jiahu region of China. The analysis of that pottery showed a combination of residues from barley, honey, and rice, along with grape and/or hawthorn berry. Using this information, Dogfish Head and "Dr. Pat" (as he's known to many people) created a beer they called Chateau Jiahu.

Quick notes regarding my changes versus the published recipe:

What I also found was that the hawthorn berry powder made a mess in the kettle and apparently scorched on the bottom. If I was doing this recipe again, I think I'd try putting the powder in a fine mesh bag rather than in the kettle itself.

This was a beer I was very fond of from the first sip. It has a flavor that immediately invokes a combination of sake (rice wine), beer, and mead, with a mild sweetness from the hawthorn berry. It's incredibly easy to drink despite the higher ABV.

Dr. Pat's book Ancient Brews - Rediscovered and Recreated contains a malt-extract-based recipe to recreate the beer.

I brewed a batch of this a while back, and it turned out quite well. For this batch, I'm swapping out the (4 pounds of) light or extra-light malt extract for some Pilsner malt. This should reduce the cost and possibly bring the flavor closer to the Dogfish Head original.

Ingredients

9 pounds Briess Pilsner Malt

3 pounds Orange Blossom Honey

2 pounds Rice Syrup Solids, switched for 8 cups cooked long-grain rice at brew time

1 pound White Grape Concentrate (used for wine-making, Muscat if you can get it)

8 ounces Hawthorn Berry Powder

1/2 ounce Sweet Orange Peel

1/4 ounce Bitter Orange Peel (not in the original recipe, my addition)

1/4 ounce Bitter Orange Peel (not in the original recipe, my addition)

1/4 ounce (17 IBUs worth) of Simcoe hops, switched for 1 oz. Mandarina Bavaria at brewing

1/4 tsp. Brewtan B (15 min.)

1/2 tsp. Yeast Nutrient (15 min.)

1/4 Whirlfloc tablet

1/4 tsp. Brewtan B (15 min.)

1/2 tsp. Yeast Nutrient (15 min.)

1/4 Whirlfloc tablet

1 package Fermentis Safbrew Abbaye, White Labs WLP530, or Wyeast 3134 Sake yeast

3.5 gallons mash water

2.75 gallons sparge water

Quick notes regarding my changes versus the published recipe:

- Too late in the mash I realized I didn't have the rice syrup solids. At the last minute, I quickly cooked eight cups of traditional long grain rice on the kitchen stove and added them into the mash, extending it by 45 minutes. An iodine test showed full conversion but there seemed to be quite a lot of the rice kernels left after mashing.

- I added Bitter Orange peel because I liked dialing up the orange flavor in the beer a little.

- I also switched from Simcoe in the original recipe to Mandarina Bavaria hops because those also add a mandarin orange note that should complement the beer.

- I couldn't get Muscat grape concentrate in any reasonable quantity and price, but Label Peelers sold me a liter of white grape concentrate at a decent price, so I went with that.

- Whirlfloc was added to brighten the beer.

- Brewtan B was added to help stabilize the flavor.

- Yeast nutrient was added since it's a somewhat high gravity beer

- I used Lallemand Abbaye Ale Yeast, as I was out of the others listed. This package turned out to be bad, so I supplemented it with a fresh package of SafAle T-58.

Per Brewfather, the resulting brew should have the following characteristics:

- Batch Size: 5 gallons estimated (and actual)

- Original Gravity: 1.084 SG estimated, 1.083 SG actual per Tilt

- Pre-Boil Gravity: 1.055 SG estimated, 13.1 Brix (1.051-1.053 actual)

- Pre-Boil Volume: 5.3 gallons (20L)

- Final Gravity: 1.014 SG estimated, 1.017 SG actual

- ABV: 9.8% estimated

- SRM: 3

- IBUs: 18

- Brewhouse Efficiency (calculated post-brew): 77%

- Fermenter Used: Chapman Stainless 7-gallon

- Bottling Wand Used: new thin plastic model

- Carbonation Method: 4 Brewer's Best conditioning tablets per 12-ounce bottle, 8 per 22-ounce bomber bottle

Mash process:

- Fire up The Grainfather and add a quarter of a Campden Tablet to help remove any chlorine and chloramine from the brewing water (Dublin Ohio tap water)

- Heat from 61F ambient water temp to 120F

- Mash in at 120F and hold at 120F for 25 minutes

- Raise to 140F and hold for 15 minutes

- Raise to 156F and hold for 45 minutes

- Note: About 15 minutes into this step I realized that I didn't have the rice syrup solids. I quickly cooked 8 cups of long-grain rice and added it to the mash. I then extended the mash by 45 minutes. This appears to have done the trick as I did hit my OG.

- Mash out at 168F and hold for 10 minutes

- Sparge with 168F water until dripping stops, while also heating wort to boiling

Boil process:

- 60 minutes: (In the original recipe, you add rice syrup solids here. Since I used cooked rice, I did not add anything here.)

- 30 minutes: Add hawthorn berry powder

- 15 minutes: Add Mandarina Bavaria hops, whirlfloc

- 10 minutes: Add sweet/bitter orange peel, yeast nutrient

- 0 minutes: Add honey and begin chilling to yeast-safe temperature

Fermentation plan:

- Ferment in the upper third of the yeast's range for days 1-7

- Continue fermenting at ambient temperature for days 7-14

Bottle using three small Brewer's Best Conditioning Tablets per bottle (low carbonation).

Post-Brew Notes and Observations

04/26/2020: The Pilsner malt used in the batch was a mix of about 3 pounds of Swaen Pilsner, 3-4 pounds of Dingeman's Belgian Pilsen, and the rest Weyermann's German Pilsner, for a total of 9 pounds.

About 45 minutes into the mash, I realized I had no rice syrup solids. The best I could do as a substitute was to quickly cook 4 pounds of long-grain rice on the stove and add them into the mash tun, giving the mash another 45 minutes to convert the rice. How will this impact the finished beer? No idea.

In retrospect, although adding all this rice did allow me to reach my target gravity, I suspect that a large amount of the starch did not convert because the kernels remained intact. If I was doing this again, I'd use a blender or similar tool to grind the cooked rice into a paste that would make the starch more accessible to the amylase enzyme. (Actually, if I was doing it again, I would actually use the rice syrup solids, as that's a lot less work.)

I went looking for my Simcoe hops and discovered a one ounce package of Mandarina Bavaria hops at 10.1% Alpha Acid (AA). A quick check in Brewfather revealed that adding this exact amount at 15 minutes from the end of the boil would hit my IBU target, and might result in the hop's mandarin orange flavors coming out, enhancing the beer (hopefully). That seemed like a bit of synchronicity, so I went with it.

I used Lallemand Abbaye yeast for fermentation, pitched right from the package. The yeast's optimal fermentation range is 63-77F, which is well within ambient temperatures in the basement. I don't expect the temperature to go much about 68-69F during fermentation and won't bother using temperature control for this batch.

After transferring the wort to the kettle and dropping in the Tilt Hydrometer, I found that I had five gallons of wort at 1.084 SG. That's exactly what Brewfather had calculated, but is a few points shy of the OG listed in Dr. Pat's book... not enough to stress over, though.

About 45 minutes into the mash, I realized I had no rice syrup solids. The best I could do as a substitute was to quickly cook 4 pounds of long-grain rice on the stove and add them into the mash tun, giving the mash another 45 minutes to convert the rice. How will this impact the finished beer? No idea.

|

| My emergency replacement for rice syrup solids |

I went looking for my Simcoe hops and discovered a one ounce package of Mandarina Bavaria hops at 10.1% Alpha Acid (AA). A quick check in Brewfather revealed that adding this exact amount at 15 minutes from the end of the boil would hit my IBU target, and might result in the hop's mandarin orange flavors coming out, enhancing the beer (hopefully). That seemed like a bit of synchronicity, so I went with it.

I used Lallemand Abbaye yeast for fermentation, pitched right from the package. The yeast's optimal fermentation range is 63-77F, which is well within ambient temperatures in the basement. I don't expect the temperature to go much about 68-69F during fermentation and won't bother using temperature control for this batch.

|

| Wort at the 5 gallon mark, with Tilt Hydrometer, before yeast pitch |

What I also found was that the hawthorn berry powder made a mess in the kettle and apparently scorched on the bottom. If I was doing this recipe again, I think I'd try putting the powder in a fine mesh bag rather than in the kettle itself.

|

| The scorch, soaking in hot PBW |

Removing the mess wasn't too terrible, but required soaking for a while with PBW followed by a bit of scraping and scrubbing. It was bad enough that it tripped The Grainfather's scorch protection switch during cleaning, and I had to reset it.

As I write this at about 10:40pm on April 26, the Tilt Hydrometer reports a temperature of 65F within the fermenter and a gravity of 1.083 SG, which occasionally blips at 1.084 SG.

04/27/2020 (Day 1): It's now about 13 hours since yeast pitch. The temperature of the beer has held at 65F and the gravity continues to read 1.083 SG. I suspect that will change in the next few hours once the yeast begins fermenting in earnest.

04/28/2020 (Day 2): Gravity still reads 1.083 SG with an occasional blip of 1.082 SG, which suggests that fermentation might be starting, finally. (Update 12:25pm: There was absolutely no indication of live yeast or yeast activity in the fermenter, which I am not surprised by when I saw the packet had expired in 2018 without my realizing it. I pitched a fresh, good packet of SafBrew T-58 to replace it.)

04/29/2020 (Day 3): Gravity is now 1.076 and temperature reads 67F. Looks like the T-58 yeast is doing just fine in its new habitat. (Update 1:50pm: The temp reached 69F, so I used a bungee cord to strap some ice packs to the fermenter to help cool down the beer.)

04/30/2020 (Day 4): Overnight, gravity dropped to 1.040 but the temp jumped to 72F, which is about 4 degrees higher than I wanted it to get. I strapped a large ice pack to the fermenter at 9am, and it had gotten down to 66F by around 2pm.

05/01/2020 (Day 5): Gravity is now 1.027 SG and the temp has been holding at 66F, so it appears that fermentation is slowing down now. We're still about 13 points from the expected final gravity, so hopefully the ice pack yesterday didn't make the yeast go dormant.

05/04/2020 (Day 8): Gravity is down to 1.019 today and temperature has been within 66F and 67F since added the ice pack three days ago. I think it's likely we'll hit the 1.015 estimated FG by the weekend, when I may be able to bottle it. We'll see.

As I write this at about 10:40pm on April 26, the Tilt Hydrometer reports a temperature of 65F within the fermenter and a gravity of 1.083 SG, which occasionally blips at 1.084 SG.

04/27/2020 (Day 1): It's now about 13 hours since yeast pitch. The temperature of the beer has held at 65F and the gravity continues to read 1.083 SG. I suspect that will change in the next few hours once the yeast begins fermenting in earnest.

04/28/2020 (Day 2): Gravity still reads 1.083 SG with an occasional blip of 1.082 SG, which suggests that fermentation might be starting, finally. (Update 12:25pm: There was absolutely no indication of live yeast or yeast activity in the fermenter, which I am not surprised by when I saw the packet had expired in 2018 without my realizing it. I pitched a fresh, good packet of SafBrew T-58 to replace it.)

04/29/2020 (Day 3): Gravity is now 1.076 and temperature reads 67F. Looks like the T-58 yeast is doing just fine in its new habitat. (Update 1:50pm: The temp reached 69F, so I used a bungee cord to strap some ice packs to the fermenter to help cool down the beer.)

04/30/2020 (Day 4): Overnight, gravity dropped to 1.040 but the temp jumped to 72F, which is about 4 degrees higher than I wanted it to get. I strapped a large ice pack to the fermenter at 9am, and it had gotten down to 66F by around 2pm.

05/01/2020 (Day 5): Gravity is now 1.027 SG and the temp has been holding at 66F, so it appears that fermentation is slowing down now. We're still about 13 points from the expected final gravity, so hopefully the ice pack yesterday didn't make the yeast go dormant.

05/04/2020 (Day 8): Gravity is down to 1.019 today and temperature has been within 66F and 67F since added the ice pack three days ago. I think it's likely we'll hit the 1.015 estimated FG by the weekend, when I may be able to bottle it. We'll see.

05/05/2020 (Day 9): Gravity is reading 1.018 SG. Temp 66F.

05/06/2020 (Day 10): Gravity 1.018 SG, temp 65F today.

05/07/2020 (Day 11): Gravity as measured by the Tilt Hydrometer is bobbing back and forth between 1.017 SG and 1.018 SG, and temp is reading 64F.

05/10/2020 (Day 14): Gravity has held at 1.017 SG and temp at 64F, since about 1pm Friday. If it holds at this gravity for at least 7 days straight, it will be time to bottle it.

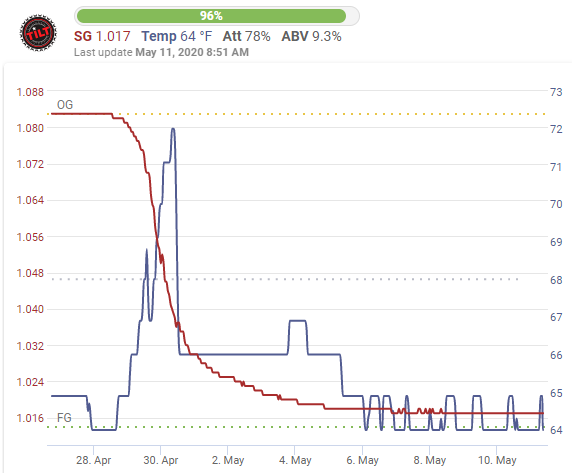

05/11/2020 (Day 15): Below is a screencap from Brewfather showing the gravity and temperature for this brew from yeast pitch to date. We're currently holding at 1.017 SG and 64F, which is close enough to the expected final gravity of 1.014 SG that I suspect fermentation is finished... but I still plan to give it a few more days to be sure.

05/12/2020 (Day 16): Gravity has held at 1.017 for about 4 days now with no indication that it's dropping further. Odds are good that I'll be bottling this one Saturday or Sunday.

05/14/2020 (Day 18): Gravity and temp have continued to hold for about 6 days at this point, so unless things change today or Friday, I'll be bottling it this weekend.

05/23/2020 (Day 27): Gravity has held at 1.017 for a couple of weeks. My wife and I bottled the beer today. Yield was 12 bomber bottles (22oz.) and 24 standard 12-ounce bottles. A taste of the beer from the fermenter was just about perfect. The aroma was fruity and floral. The mouthfeel was medium to light bodied. There was just a touch of warming alcohol. The flavor was a nice mix of mead, sake, and beer, being not too much of any one of those, and extremely tasty. Priming sugar was added to deliver a medium level of carbonation (4 Brewer's Best tablets per 12-ounce, 8 per 22 ounce).

Comments

Post a Comment

Note that comments to this blog are moderated in order to minimize spam comments and things that might be offensive to readers.